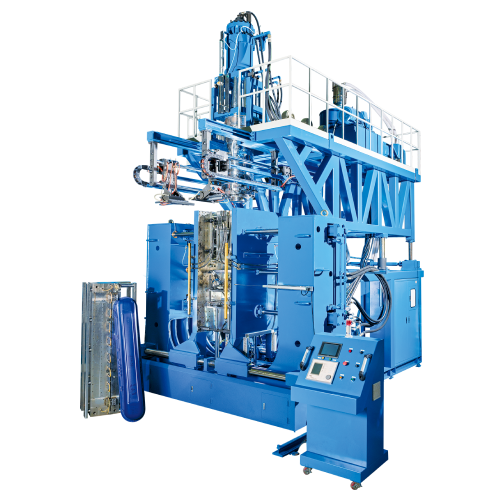

Large Blow Molding Machine

Categories : Horizontal Blow Molding Machines

Large –Accumulator Die Head Type Blow Molding Machine These series models are suitable for productions ranging from 30L up to 130L whether for barrels, pallets, toys, water storage tanks, floats, automobile parts, and narrow or full open mouth drums applications. This machine is suitable for blowing irregular-shaped plastic products. Applications of a large accumulator blow molding machine include the following: Barrels 2-mouth jerry cans Toys Water storage tanks/ PC water jugs Paddle wheel aerator floats Air duct and other automobile parts Baby safety seats Cooler box/ice bucket Sports equipment Narrow mouth and full open mouth drums For certain products, we have developed a high-speed model of this series for customers that need a high production output.

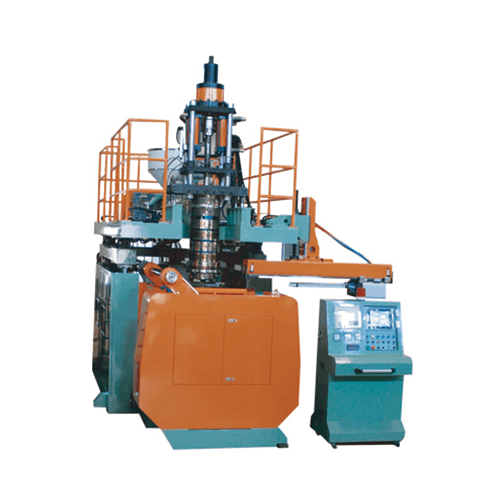

Automatic Blow Molding machine-I Series

Categories : Automatic Blow Molding Machines

Full Shine's I Series Blow Molding Machines are suitable for producing large and various plastic products, such as tool boxes, water tanks, beer drums, jerry cans, and automobile components. These machines are equipped with accumulator-type mold heads and multi-point parison controllers. These machines are with lateral take-out mechanism. Machine frame and die head are movable for replacing molds easily.

Automatic-Blow-Molding-machine-L Series

Categories : Automatic Blow Molding Machines

Full Shine's L Series Blow Molding Machines are suitable for producing big and large containers, such as water tanks, chemical drums, jerry cans, and automobile components. These machines are equipped with accumulator-type mold heads and multi-point parison controllers. Mold carriages are perpendicular and easy for producing different-shaped products.

Blow Molding Machine PBS 905PC SERIERS

Categories : Automatic Blow Molding Machines

The PBS-905PC Special Purpose Blow Molding Machine is specially designed with an advance German type die head, featuring "first-in, first-out" performance. It is ideal for producing high quality, high clarity and high gloss PC water tanks. The machine is suitable for producing 2.5~5 gallon containers.

Accumulator Head Blow Moulding Machines-Water Pressure Tank

Categories : Extrusion Blow Molding Machines

Mono Layer and Multi-layer Accumulator Head Type Blow Moulding Machine. For producing 20 liter to 1000 liter volume, all kinds of jerry can, containers, air duct and industrial blow moulding products.

Accumulator Head Blow Moulding Machines–400L-600L Fuel Tank

Categories : Extrusion Blow Molding Machines

Accumulator Head Blow Moulding Machines For 400L-600L fuel tank

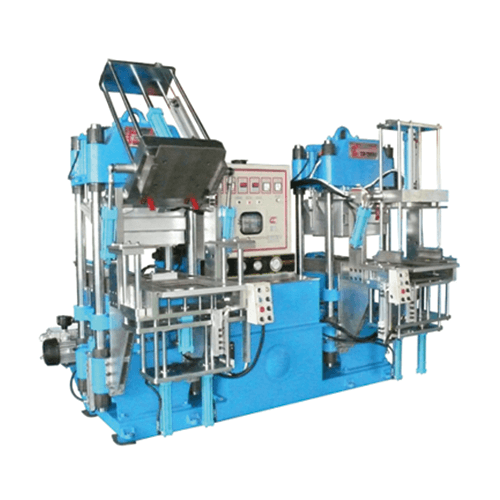

4RT Mold-Open Oil-Seal Vacuum Compression Molding Machine VOCC-D3W

Categories : Shoe Sole Making Machines

Design for machine frame The machine frame is made of steel plates through assembly. It is suitable for the production of oil seals. Design for loading/unloading molds Abrasive components are installed on the frame for loading/unloading molds. It can be frequently used and it’s positioning is very accurate. Design for vacuum room A vacuum gate can be opened or closed very quietly and smoothly. The tightness is excellent and it is capable of being high percentage of vacuum. Design for oil tank The vacuum room and the oil tank are separated to make oil seals more durable. Design for final products Two openings are designed for final products, top and bottom. The operation is easy and the production speed is very fast. Maintenance All positioning switches are installed outside the vacuum room. It becomes more durable and it is easier to perform the maintenance work. Oil system design Each oil system is designed respectively. Two shafts can be operated simultaneous.